lifeboats compressed air hydroustatically tested|lifeboat inspection checklist : OEM October 28, 2024 Safety Alert 08-24 Washington, DC. presence of dissimilar metals. Although stray electrical currents were considered as a potential cause, they were deemed unlikely . Fases do processo seletivo. Quero ser Bayer. Avaliação Téc.

{plog:ftitle_list}

web8 de nov. de 2018 · Sony a7III Dual Card Setup. In order to setup the dual card slots you will need to jump into that infamous Sony menu system, so simply hit the MENU button on the a7III and you should be greeted by the following menu. If you don’t see this exact menu then you will need to select the “Camera 1” icon from the top menu tabs.

air support bottles shall also be hydrostatically tested prior to refilling a bottle that has been discharged. The hydrostatic test date must be permanently marked on the bottles or, if the .

As per MSC.1/Circ.1452, all breathing apparatus cylinders, independent of their construction material shall be hydrostatically tested at 5-year intervals, unless the manufacturer specifies a .

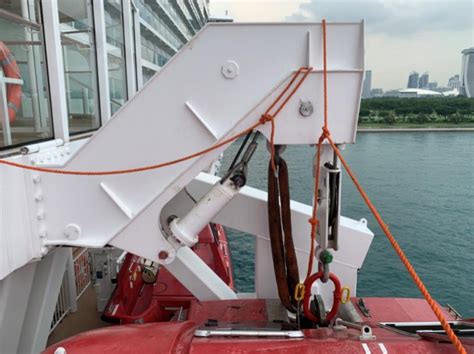

October 28, 2024 Safety Alert 08-24 Washington, DC. presence of dissimilar metals. Although stray electrical currents were considered as a potential cause, they were deemed unlikely .Each prototype lifeboat of each design must pass each of the tests for davit-launched or free-fall lifeboats, as applicable, described in the IMO Revised recommendation on testing, part 1, .Hydrostatic testing: A hydrostatic test is carried out to check the cylinder’s strength and ensure it can withstand the required pressure. This test is typically carried out every five years, or more frequently if required by the manufacturer.Air bottles in totally enclosed lifeboats should be internally and externally inspected and hydraulic pressure tested at intervals not exceeding 5 years and the hydrostatic test date must be .

lifeboat towing requirements

During this period the atmospheric pressure inside the lifeboat shall never fall below the outside atmospheric pressure nor shall it exceed it by more than 20 hPa. The system shall have visual .

(IACS Recommendation No.88: Air bottles for air supply in totally enclosed lifeboats should be hydraulic pressure tested by a competent service station recognised by a Recognised .j. all fire hoses are hydrostatically tested; k. All Self -contained breathing apparatus (including SCBA ¶s on lifeboats) should be checked for external condition and air recharging systems .

Totally Enclosed Free Fall Lifeboat designed and manufactured according to latest SOLAS requirements. The lifeboat provides a secure and protected means of escape for persons . Unlocking the Power of Precision: Hydrostatic Cylinder Testing ensures safety and reliability of pressure vessels. Explore the significance of ASME hydrostatic testing, its procedures, and compliance with regulatory .

lifeboat rail sizes

The SOLAS amendments address maintenance, thorough examination, operational testing, overhaul and repair of lifeboats and rescue boats, launching appliances and release gear. A set of important amendments .

The inspection and testing requirements for scuba cylinders may be very different from the requirements for other compressed gas containers due to the more corrosive environment in which they are used. [2] . Three cylinders from each batch are pulsation hydrostatically tested for 10,000 cycles from 0 to test pressure at 12 cycles per minute .A lifeboat or liferaft is a . Tankers are required to carry fireproof lifeboats, tested to survive a flaming oil or petroleum product spill from the tanker. Fire protection of such boats is provided by insulation and a sprinkler system which has a pipe system on top, through which water is pumped and sprayed to cool the surface while the boat .The markings are normally stamped into the shoulder of the cylinder. The hydrostatic test date and inspector mark indicate when the cylinder was last tested and who tested the cylinder. Most cylinders are required to be tested every 5 years. This test ensures the cylinder can safety hold the maximum fill pressure.recovery) and when the lifeboat has crew or other personnel aboard. After the drill finishes, the secondary safety system must be removed or disengaged. 3.2 Air Cylinders Lifeboat air cylinder inspection and maintenance must be performed according to RMI Marine Notice 2-011-14. Air cylinders in totally-enclosed lifeboats must undergo

lifeboat overload test requirements

VIKING Project No.: TBA VIKING Doc. No.: TSB-0013 Rev. Date: 12.08.2019 Rev. No: 2 3 Compressed air system (tank ver.) 6 x 50 liter air bottles, air regulator and high pressure hoses Under/overpressure valves Automatic spring loaded on canopy Loose equipment According to SOLAS Totally Enclosed Lifeboat (TELB) designed and manufactured according to latest .Hydrostatic testing is also required by law for certain types of cylinders. For example, DOT regulations require that all compressed gas cylinders used for transportation be hydrostatically tested at specified intervals. Failure to comply with these regulations can result in fines, legal liability, and damage to your reputation.

CYLINDER HYDROSTATIC TESTING We perform visual inspection as well as government controlled (TC#047) and certified hydrostatic testing of cylinders of all sizes. We can also refill all SCUBA and SCBA cylinders with laboratory tested, clean, dry breathing air and CO2 cylinders with fresh carbon dioxide eliminating the need to make a second stop before getting back to .In addition to complying with the requirements of section 4.6 or 4.7, as applicable, a lifeboat with a self-contained air support system shall be so arranged that, when proceeding with all entrances and openings closed, the air in the lifeboat remains safe and breathable and the engine runs normally for a period of not less than 10 min.

In its recent version of Safety Flashes, IMCA analyze a case where there was a structural failure of an air cylinder fitted in a lifeboat. . Hydrostatic [pressure] tested at a required interval of five years. Tags: IMCA lessons learned safety campaign safety culture safety measures sm. Previous Post Watch: How digitalization optimizes .

Air cylinders shall be hydrostatically tested every 5 years. the hydrostatic test date must be permanently marked on the bottles. Attached: bulletin “MARS-201165 Lifeboat damaged by ruptured air cylinders . MARS 201165 Lifeboat damaged by ruptured air cylinders . of the compressed air cylinders suddenly and spontaneously burst, resulting in .Hydrostatic testing. Hydrostatic testing is an essential part of quality control and is the industry standard for most testing. These tests are performed to determine the safety and structural integrity of a variety of objects including gas cylinders, storage tanks, plumbing systems and chemical pipelines.NFPA 12 requires high pressure carbon dioxide cylinders to be emptied and hydrostatically tested every 12 years. (See NFPA 12 2011 edition 4.6.5.2.2.) DOT regulations do not require undamaged charged cylinders to be removed from service, .Hydrostatic testing can be defined as the process of subjecting a material to a controlled pressure and observing how it reacts to the pressure. The test is. . The name comes from when engineers used compressed air as their .

Aluminum cylinders (not including hoop-wrapped) should be tested every five years. They have an indefinite service life provided they pass hydrostatic testing. Hoop-wrapped cylinders should be tested every three years. Hoop-wrapped cylinders have a 15-year service life. Fully wrapped berglass cylinders should be tested every three years.Study with Quizlet and memorize flashcards containing terms like 1. When pressurizing a refrigeration system with nitrogen, what rule should you always follow? A. Charge nitrogen as a liquid. B. Use a pressure regulator with a pressure relief valve on the nitrogen cylinder. C. Pressurize to above 1000 psig. D. Never use nitrogen inside the system, 2. Why should .The primary difference between aviation breathing oxygen and other types of commercially available compressed oxygen is that. . An aircraft oxygen bottle may be considered airworthy if it has been hydrostatically tested and identified. with the test date, DOT number, and serial number stamped on the cylinder near the neck.Hydrostatic testing is the preferred method of testing because it generates considerably less stored energy and thus involves less risk to workers. In this type of testing, a liquid, usually water, is pumped into the system before it is pressurized with air or gas. Water can’t be compressed like the air or gas used by itself for pneumatic

lifeboat overload test

.4 air supply system, where fitted; .5 manoeuvring system; .6 power supply system; .7 bailing system; .8 fender/skate arrangements; and .9 rescue boat righting system, where fitted. . TESTING, OVERHAUL AND REPAIR OF LIFEBOATS AND RESCUE BOATS, LAUNCHING APPLIANCES AND RELEASE GEAR. RESOLUTION MSC.402(96) (adopted on 19 May 2016) . A hydrostatic test is a test for the pressure vessel to test its strength and leak tightness by pressurizing the vessel using incompressible liquid up to the test pressures recommended by the standards. A pressure vessel is a closed container that holds the fluid at a pressure either higher or lower than the ambient pressure.

Safety Equipment Lifeboat / Liferaft Accessories Testing Device for Immersion Suits . 330199 AIR COMPRESSOR PORTABLE FOR, IMMERSION SUIT TESTING DEVICE. IMPA Code: 330199. UOM: SET. MTML UOM: SET. An Air compressor with storage compartment designed for use with the Universal Testing Device for Immersion Suits.

Service/maintenance of various brands of marine lifeboats including the overhauling of main/on-load release hook mechanism, repair to fiberglass boat hull, servicing of compressed-air system, servicing of sprinkler system, servicing/overhaul of engine and steering gears, etc. Voyage repairs for lifeboats and launching appliances. A lifeboat air cylinder is an essential component of a lifeboat’s air supply system. It provides compressed air to inflate the lifeboat’s buoyancy chambers and operates the lifeboat’s air-driven machinery. The cylinder is typically made of high-strength steel and is designed to withstand the harsh marine environment. 40 psi is typically used for air testing. NFPA-13 permits interim air tests for certain applications (ie, systems subject to freezing, dry-systems, preaction systems). The parameters are specified in Section 25.2.2 of the 2016 edition. Assuming all stakeholders (AHJ, ownership, insurance carriers, etc) agree that an air test is acceptable.

All compressed gas cylinders have to be hydrostatically tested every 10 years to ensure they are safe and fit for purpose. Gielle has in-house test facilities to enable us to carry out cylinder testing. . A “hydro test” is an approved way to test the structural integrity of a compressed gas container. It is performed by removing the valve .Hydronic piping systems shall be tested hydrostatically at one and one-half times the maximum system design pressure, but not less than 100 psi (689 kPa). . testing with a compressed gas shall be an alternative to hydrostatic testing where compressed air or other gas pressure testing is specifically authorized by all of the manufacturers .

lifeboat inspection checklist

lifeboat enclosure requirements

web13 de jan. de 2017 · Here are some exchange services worth reading up on before you go. Travelex Locations. Travelex has three main locations in Las Vegas. | --- | --- | | Locations | Contact Information | | Las Vegas .

lifeboats compressed air hydroustatically tested|lifeboat inspection checklist